We get the pleasure of restoring some very unique vehicles and this one definitely falls into that category. This 1970 Galaxie coupe has an interesting history. This car was a Caribbean export model that was shipped directly to Puerto Rico from the factory in the US. These special models had no heater, defroster, AC or even a fan. We can understand not needing a heater in the tropics but I think a fan might have been nice… In any event, the factory just installed block off plates where all those parts should have been. The car managed to survive the salt air from 1970 to 2015, when it was shipped back to the U.S. The current owner spotted this giant coupe for sale a few years ago and couldn’t resist. David used it as his daily driver for a while then decided to start a restoration on it with his son Jackson. These projects always turn into more than expected and finding time to finish the car can become a problem. At that point, David decided to turn the project over to us.

When we received the Galaxie it looked pretty nice. It was basically original including the drive train and had really low miles. We were thinking this would be a simple restoration but David warned us of significant rust issues. He and Jackson had already modified the suspension to get the stance right and had started some of the rust repair.

Our first step was to get the mechanical side of things sorted out. The car had been sitting for a while and needed some TLC. We also didn’t savor the idea of having to push a car this big around the shop. Once it was running well we started digging into the body.

The Caribbean air had not been kind to the old car. Underneath some older body work was extensive rust damage.

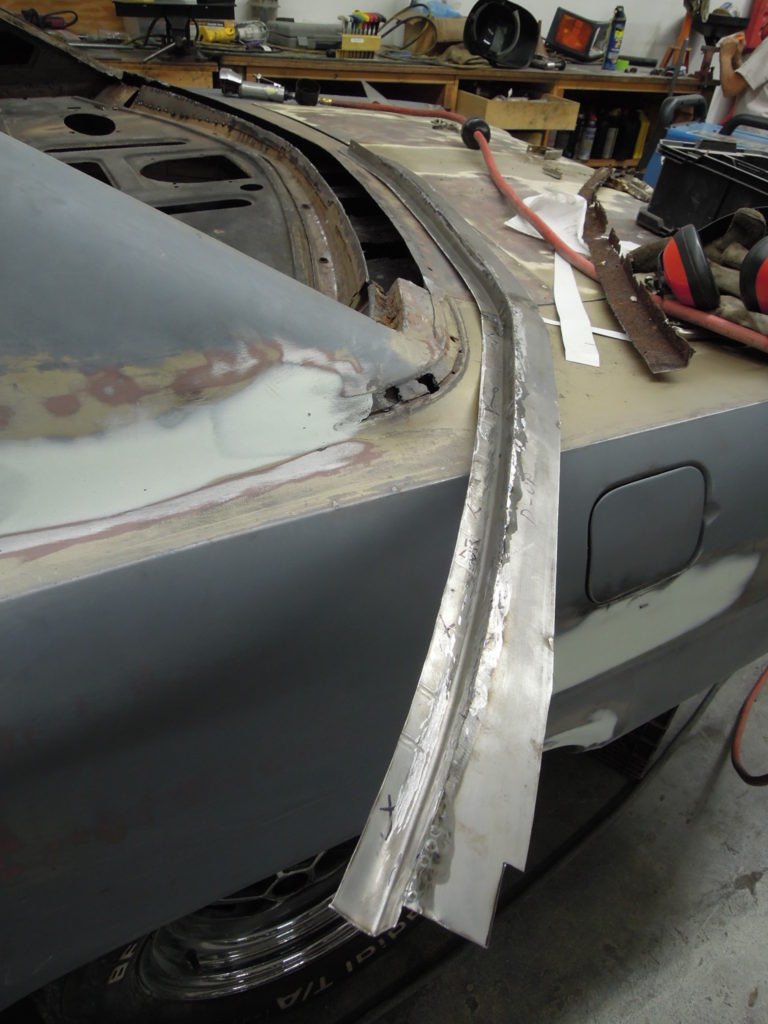

No one makes reproduction body parts for this car so it was “fabrication time”. We did body reconstruction on virtually every part of the car except the roof. For some reason that part stayed rust-free. Here are some of the challenges we faced.

David chose Nardo Gray for the exterior color and multi-tone black for the interior. There are very few interior parts available for these cars. Fortunately the interior panels were repairable. After we got them structurally sound we were able to dye all the vinyl surfaces and dash black.

After much searching we were able to find carpet and a replacement headliner for the interior which was a relief.

Our friends at Rayco Upholstery recovered the seats with David’s custom design after we restored and padded the frames.

The final product is so unique. The shear size of the car and the low stance give it a menacing look. The Galaxie is a great driver and really turns heads. David and Jackson have continued to refine the car since getting it back from our shop and it just keeps getting better.